Unveiling the Power of Jetting in Drilling: A Comprehensive Guide

- ProGrynd International

- Aug 18, 2023

- 2 min read

In the dynamic world of drilling, innovation continues to shape the landscape of resource extraction. Jetting, a specialized technique, has emerged as a powerful tool in drilling operations. As a leading name in advanced solutions for the energy sector, ProGrynd is excited to take you on a comprehensive journey through the realm of jetting in drilling. In this article, we delve into the fundamentals of jetting, its applications, benefits, and the role of ProGrynd in optimizing this cutting-edge technology.

Understanding Jetting in Drilling: The Basics

Jetting, also known as water jetting or hydro jetting, is a drilling technique that utilizes high-pressure water jets to create boreholes in various geological formations. Unlike traditional drilling methods that rely on mechanical force to break rock formations, jetting harnesses the power of water to cut through the subsurface.

The Mechanics of Jetting: How Does It Work?

Jetting involves the use of high-pressure water jets directed at the target formation. The process entails several key steps:

1. High-Pressure Water Injection:

Water is pressurized to create a high-velocity jet.

The jet is forced through specialized nozzles designed to concentrate the water's force.

2. Erosion and Cutting:

The high-velocity water jet erodes the rock formations it encounters.

The continuous flow of water causes the formation to break apart, creating a borehole.

3. Removing Cuttings:

The cuttings created by the jetting process are carried to the surface by the water flow.

A mud or slurry mixture may be used to enhance the removal of cuttings.

Applications of Jetting in Drilling

Jetting has found applications in various drilling scenarios, each benefiting from its unique advantages:

Soft and Unconsolidated Formations: Jetting is particularly effective in drilling through softer, unconsolidated formations where traditional drilling methods might struggle.

Environmental Considerations: In environmentally sensitive areas, where the use of drilling fluids might be restricted, jetting provides a cleaner alternative.

Horizontal Drilling: Jetting is conducive to creating horizontal boreholes, which are essential for accessing hydrocarbon reservoirs with maximum efficiency.

Benefits of Jetting in Drilling

The use of jetting in drilling offers a range of benefits:

Reduced Environmental Impact: Jetting minimizes the use of drilling fluids, reducing the environmental footprint of drilling operations.

Enhanced Efficiency: Jetting can expedite drilling processes by effectively breaking down formations, resulting in faster drilling rates.

Access to Challenging Reservoirs: Jetting allows drilling in formations that may be challenging for conventional methods, expanding the scope of resource extraction.

Cost Savings: Jetting can lead to cost savings by reducing the need for expensive drilling mud and additives.

ProGrynd's Role in Advancing Jetting Technology

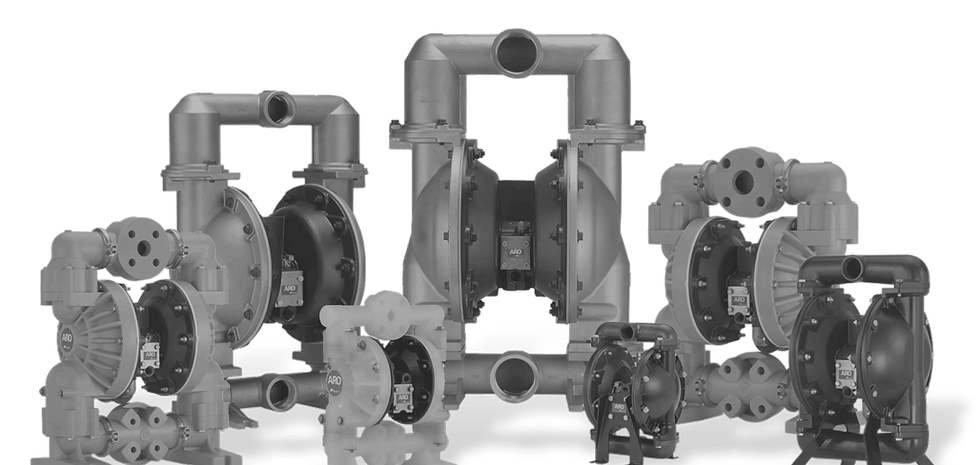

As a pioneer in the energy sector, ProGrynd is dedicated to pushing the boundaries of drilling technology. Our expertise extends to the realm of jetting, where we have developed advanced tools and solutions to optimize jetting operations. From high-precision nozzles to state-of-the-art control systems, ProGrynd empowers drilling teams with the tools they need to harness the full potential of jetting in drilling.

Conclusion:

Jetting into the Future with ProGrynd

As we explore the depths of jetting in drilling, we recognize its transformative potential in revolutionizing the way we extract resources from the Earth. ProGrynd's commitment to innovation is evident in our contributions to advancing jetting technology. With ProGrynd as your partner, you're not just drilling; you're embracing the future of drilling, where precision, efficiency, and sustainability meet in every jet of water.

Comments