Mastering the Art of Mud Rotary Drilling: A Comprehensive Guide

- ProGrynd International

- Aug 18, 2023

- 3 min read

In the realm of drilling techniques, mud rotary drilling stands as a fundamental method that has revolutionized the exploration of natural resources. With its effectiveness in accessing subsurface formations and collecting crucial data, mud rotary drilling plays a pivotal role in the oil and gas industry. ProGrynd, a leading innovator in drilling solutions, invites you to delve into the intricacies of mud rotary drilling. In this article, we provide a comprehensive guide on how to execute this technique, emphasizing its significance in modern resource extraction.

Understanding Mud Rotary Drilling: The Basics

Mud rotary drilling, also known as rotary drilling, involves the use of a rotary bit to create a borehole by cutting through formations. The process employs a drilling fluid, commonly referred to as "mud," to carry cuttings to the surface. This technique is widely used due to its ability to penetrate a variety of formations, its efficiency in collecting subsurface data, and its adaptability to different geologic conditions.

The Step-by-Step Process of Mud Rotary Drilling

Mud rotary drilling involves several key steps, each contributing to the successful execution of the technique:

1. Site Preparation:

Before drilling commences, the drilling site is prepared by clearing vegetation, establishing a stable drilling platform, and ensuring safety measures are in place.

2. Rig Setup:

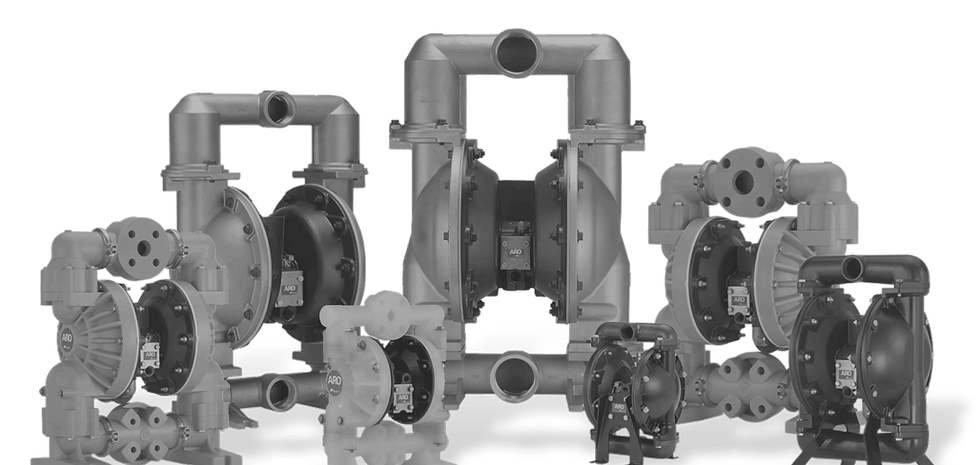

The drilling rig is set up on location, complete with the necessary equipment such as the rotary table, drilling mud system, and mud pumps.

3. Spudding In:

The initial phase involves slowly rotating the drill bit into the ground to create a small hole known as the "spud hole." This provides stability and acts as a starting point for the borehole.

4. Drilling and Circulation:

As drilling progresses, the drill bit is rotated while drilling mud is continuously pumped down the drill string. The mud serves multiple purposes: cooling and lubricating the bit, carrying cuttings to the surface, and maintaining pressure to prevent formation fluids from entering the borehole.

5. Adding Drill Pipe:

As the borehole deepens, additional sections of drill pipe are added to the drill string. The drill bit's size and type are chosen based on the formation being drilled.

6. Collecting Samples:

At specific intervals, the drilling process is temporarily paused to retrieve cuttings brought to the surface by the mud. These cuttings provide valuable insights into the geology of the subsurface.

7. Casing Installation:

Once the desired depth is reached, steel casing may be inserted into the borehole to provide structural support and prevent cave-ins.

8. Cementing and Well Completion:

After casing installation, cement is pumped into the annular space between the casing and the borehole wall to secure the well. The well is then completed by installing a wellhead and other necessary equipment.

The Role of Mud: Key Advantages

The drilling fluid, or mud, is a vital component of mud rotary drilling. Its benefits include:

Cutting Removal: Mud carries cuttings to the surface, preventing them from clogging the borehole.

Cooling and Lubrication: Mud cools and lubricates the drill bit, extending its lifespan and enhancing drilling efficiency.

Pressure Control: Mud maintains pressure in the borehole, preventing the influx of formation fluids.

ProGrynd's Innovations in Mud Rotary Drilling

ProGrynd's commitment to innovation extends to the realm of mud rotary drilling. Our advanced drilling solutions optimize mud circulation, cuttings collection, and borehole stability. By integrating cutting-edge technology and engineering, ProGrynd enhances the efficiency and effectiveness of mud rotary drilling operations.

Conclusion:

Shaping the Future of Drilling with ProGrynd

As we conclude our journey through the art of mud rotary drilling, we recognize the central role this technique plays in resource extraction. ProGrynd's dedication to innovation and excellence is evident in every facet of drilling solutions we offer. With ProGrynd as your partner, you're not just executing mud rotary drilling; you're shaping the future of drilling with precision, efficiency, and expertise. Embrace the future of drilling with ProGrynd—the innovators in drilling solutions.

Comments